Plastics

The end of life of plastics,

a major environmental challenge

Ambitions

Today's plastics combine remarkable technical properties (lightness, durability, waterproofing, flexibility or rigidity, etc.) with low cost. Mostly derived from petrochemicals, these versatile materials are currently present in all segments of our lives (packaging, textiles, buildings, transport, agriculture, the medical field...) and have been a source of progress. However, the environmental consequences induced by several decades of intensive exploitation have led to a collective awareness of the need to produce and consume differently in order to guarantee future generations a sustainable and environmentally friendly society.

Major issues

The wide use of these polymers and the fact that they often exist in mixtures makes them difficult to recycle. Today, plastic is mostly recycled by thermomechanical process. This process requires a drastic sorting upstream and does not allow to treat all the waste, and leads to a loss of properties; It is thus in reality an open loop, which does not solve the ultimate end of life of the waste.

Different bioremediation solutions considered: biological recycling process or innovative biodegradable materials.

Plastic

The shocking figures of plastic pollution

References:

- Geyer, R. Production, use, and fate of synthetic polymers. in Plastic Waste and Recycling 13–32 (Elsevier, 2020).

- Plasctics Europe. Plastics-the Facts 2020 An analysis of European plastics production, demand and waste data. (2020).

- BIOPLASTICS facts and figures. EUropeanBioplastics_Facts_and_figures2019. (2019).

(or the mass of 900,000 Eiffel Towers or 88 million blue whales)

TBI, involved in the plastic challenge

Succes Story

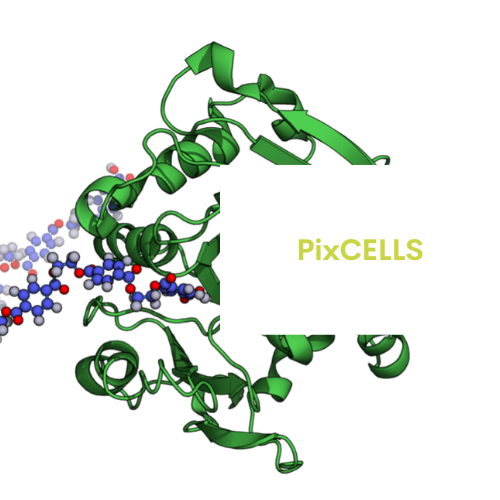

Development of an efficient enzyme for PET depolymerization by enzymatic engineering

The team CIMES, supported by the technology platform PICT-ICEO, has been working with Carbios for over 10 years.

- Development of an efficient enzyme for PET depolymerization by enzymatic engineering

- Développement d’une enzyme capable de dépolymériser par voie biologique des matériaux plastiques à base d’acide polylactique (PLA) et ce dans une large gamme de température et de pH reflétant notamment les variations naturelles que l’on peut retrouver durant le cycle de vie d’un compost domestique.

- Thanaplast Project 2012-2017 (BPI France) and Circular Economy PET Project 2018-2021 (Ademe);

- More than 10 patents filed

- Deux articles dans la revue Nature :

- Tournier, V. et al. An engineered PET depolymerase to break down and recycle plastic bottles. Nature 580, 216–219 (2020).

- Guicherd, M., Ben Khaled, M., Guéroult, M. et al. An engineered enzyme embedded into PLA to make self-biodegradable plastic. Nature (2024).

Expertise and skills

PoPlaB Cooperative Laboratory

Polymers, plastics and biotechnologies) between TBI and Carbios

Validated technology for the recycling of textile waste

Technology used to manufacture the first food-grade bottles and white fiber in 100% enzymatically recycled PET.

> read the press release

Carbiolice company

Commercializes the enzyme jointly developed by Carbios and TBI.

> Read more