Topic: Implementing microorganisms and bioreactors

A few words

Implementing microorganisms and bioreactors

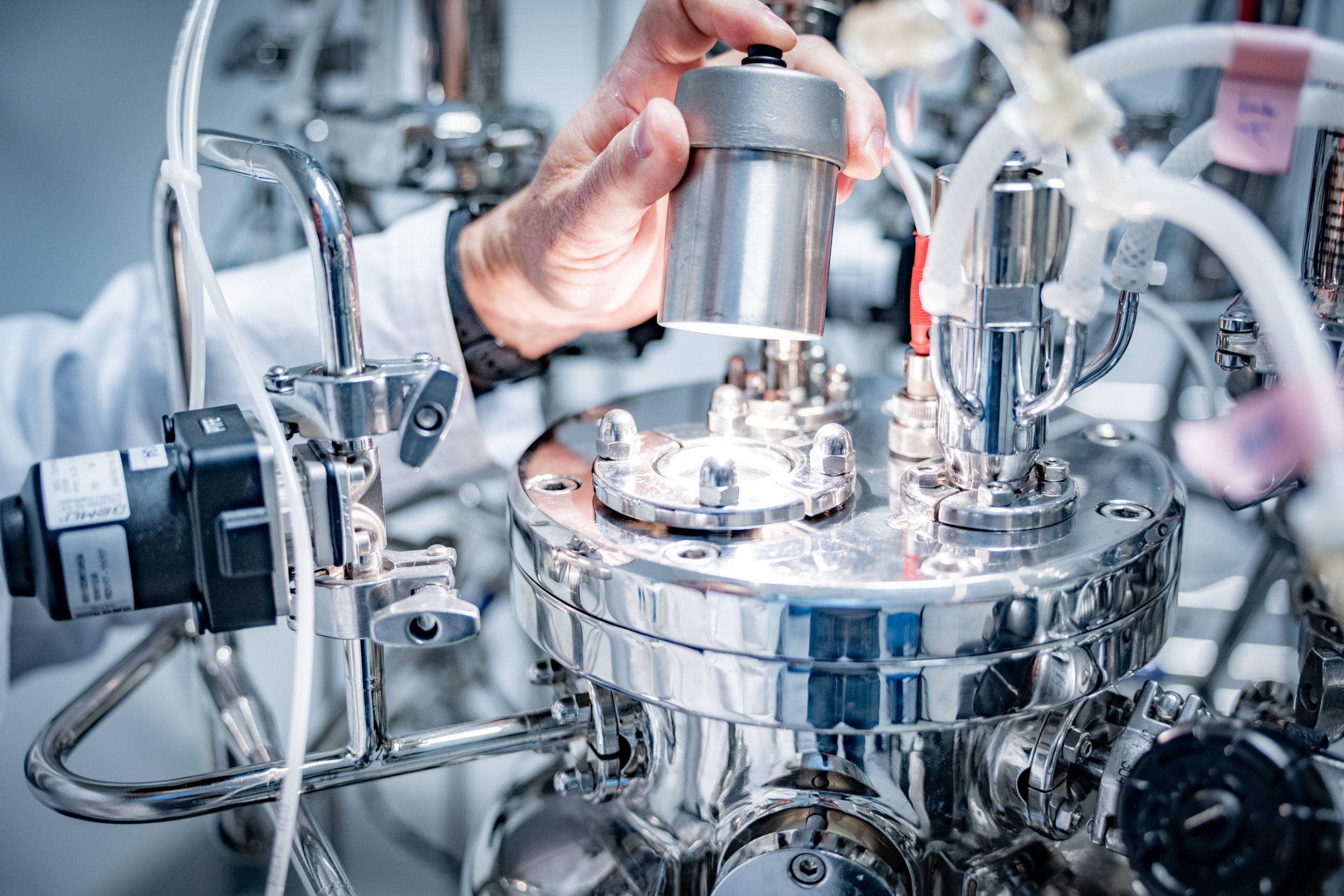

This topic focuses on evaluating microbial kinetics within bioreactors operated under specific cultivation conditions. The aim is to investigate the dynamic relationships among the process parameters, environmental factors, and microbial behavior. By doing so, we seek to pinpoint critical elements that influence microbial physiology and constrain the efficiency of microbial cell factories, thereby informing strategies for process improvement using microbiological or metabolic engineering techniques (see Topic 2). This theme also integrates bioreactor engineering based on the specificities of the fermentation studied, in particular the microorganism/substrate/product pair. In particular, the study of gaseous fermentation processes requires the development of new microbial culture systems optimized to achieve high gas transfer rates to reach high cell densities and high performances in the desired molecules. Bioreactor management strategies are then developed according to the objective of production and/or of metabolic/physiological investigation.

Ongoing projects

ConCO2rde Project

within this H2020-ITN network, the lithoautotrophic bacterium C. necator is engineered for the production of isopropanol from CO2. Gas bioreactors configuration are developed to improve gas transfer rates to increase isopropanol production performances. (High pressurized gas bioreactors, Hollow Fiber Membrane Contactor coupled to gas bioreactor)

Project CnegSAF

Hosted by CNRS@CREATE, the program ‘Carbon Negative production of advanced Sustainable Aviation Fuels using twin synthetic bacterial consortia Project’ (CNegSAF) is an international collaboration between world leading institutions in France and Singapore including Toulouse Biotechnology Institute (TBI: teams METASYS, PHYGE, CIME, BLADE), National University of Singapore, A*Star (SIFBI), and Nanyang Technological University. CNegSAF aims to demonstrate the feasibility of using a synthetic bacterial consortium to convert green hydrogen and concentrated waste CO2 (released by chemicals companies) into sustainable aviation biofuels. One of our goal is to design a new gas bioreactor and optimize fermentation strategy for cultivating the synthetic consortium with zero gas emissions.

Project Bio-Mining

Funded by the Spaceship.FR program (CNES) involves studying the feasibility of recovering mineral sources present in the regolith from microorganisms. With a view to future long-duration manned flights (Moon, Mars), the logistical autonomy of the lunar station is a major challenge and will notably require the use of local resources for the survival of astronauts. In collaboration with the PHYGE team, we are studying the integration of local mineral resources within microbial bioprocesses constituting a Life Support System.

Project BIOVAL

Within this EU Horizon-RIA project aiming at creating, developing, and scaling up an integrated energy-driven circular biorefinery with near zero-waste and zero-carbon emissions, we are investigating isopropanol production from CO2 with C. necator focusing efforts on improving strain stability for continuous gas fermentation process.